Everything You Need to Know about ASPICE (Automotive SPICE) Compliance

- Arunabh Satpathy

- July 25, 2023

- 6 minutes

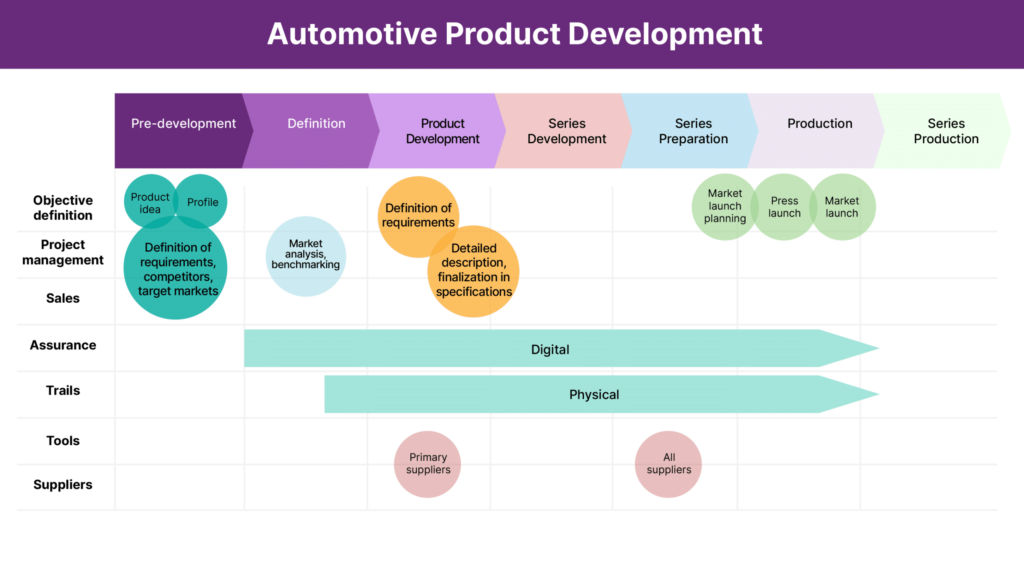

Automotive SPICE (ASPICE) is a guideline that helps automotive suppliers meet software development requirements set by OEMs (Original Equipment Manufacturers). It stands for Automotive Software Performance Improvement and Capability determination.

ASPICE is necessary because the automotive industry is increasingly driven by software at every level – from planning to production to everyday use. Even a Ford F-150 pick-up truck manufactured in 2016 contained up to 150 million lines of code. The complexity is much greater now. ASPICE gives suppliers a structured framework that helps them adopt best practices, identify defects early on, and meet OEM requirements.

This topic covers key concepts in ASPICE compliance, its benefits, and how to practically implement it in your company, with real-life examples.

Related Articles

See how it works:

Ready to streamline your requirements management today?

1. Key Concepts of ASPICE Compliance

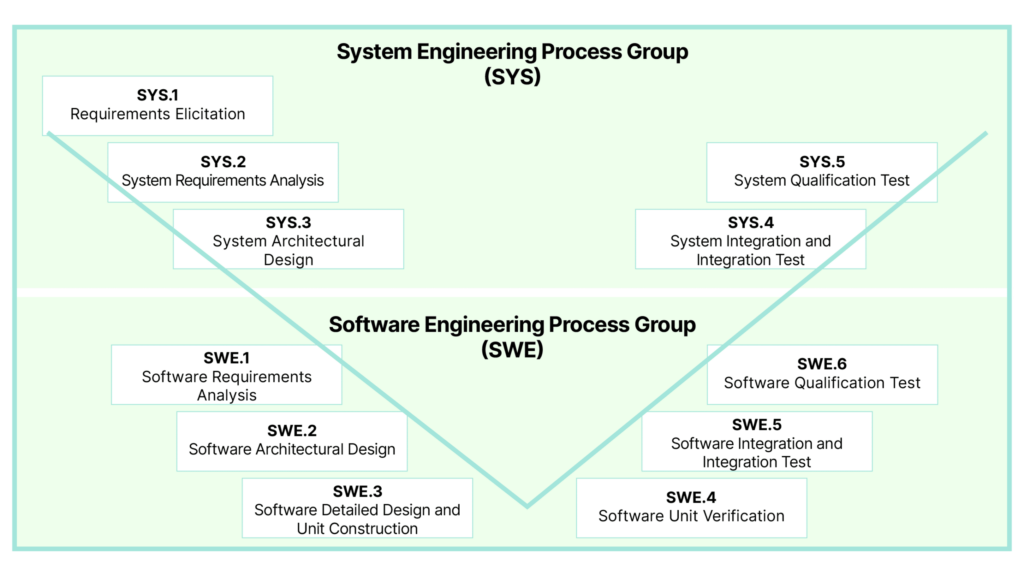

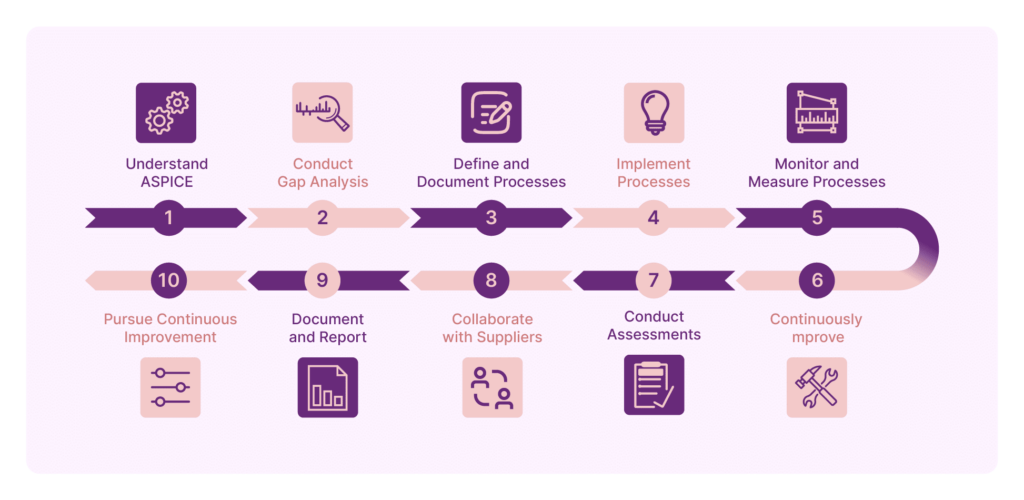

ASPICE was first developed as an automotive variant of SPICE (ISO/IEC 15504) standard, a standard for software development. It builds upon the V-model of software development, which describes the steps of software development and their relationships with one another.

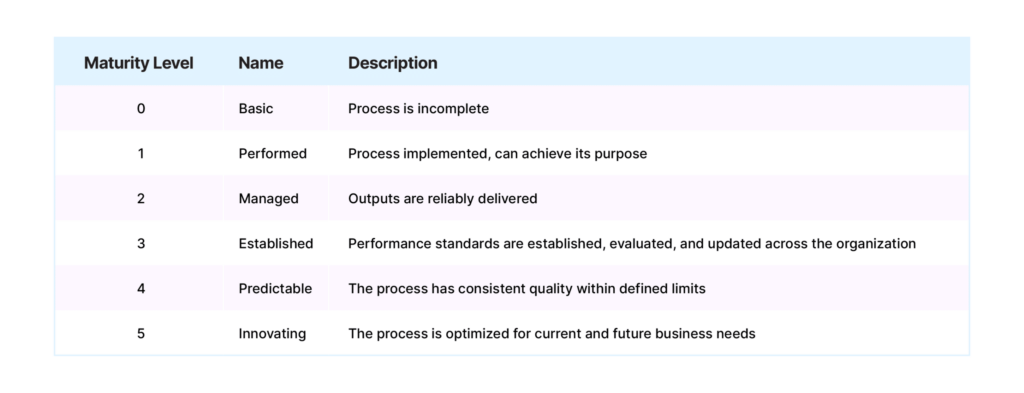

Qualified internal or external assessors periodically evaluate a supplier’s ASPICE compliance based on guidelines called the Process Reference Model. The assessment tool they use is called a Process Assessment Model; a framework which helps give the supplier’s compliance a “maturity level” from 0 to 5.

Customers for automotive suppliers prioritize Maturity Level 2 for their projects, indicating effective project management. They usually prioritize Level 3 for future projects while Levels 4 and 5 aren’t considered relevant as they are more aspirational. Most software processes are at level 2 or 3.

Each ASPICE process has some “base practices” that an organization must follow and provide evidence during evaluation to show compliance with ASPICE. For instance, the first base practice for the SYS.2 System Requirements Analysis process is SYS.1.BP1, which requires suppliers to obtain stakeholder requirements and requests.

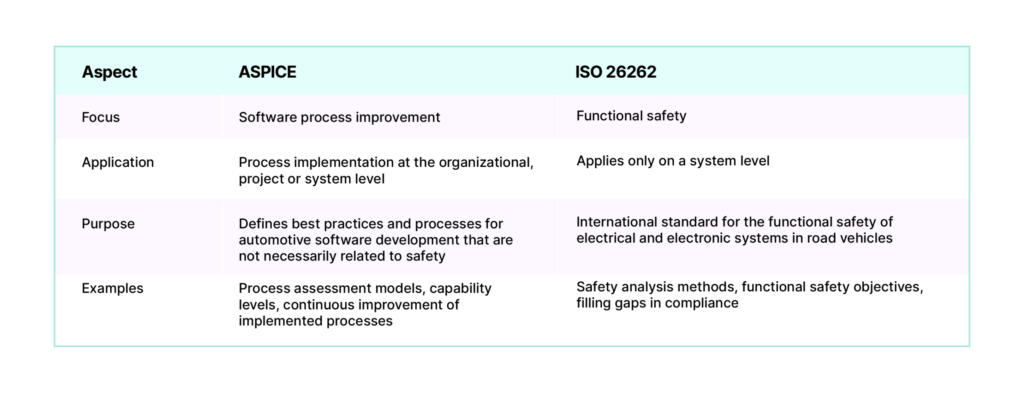

a. ASPICE vs ISO 26262

Since both these standards deal with automotive software, ASPICE and ISO 26262 are complementary, and their compliance standards may overlap. However, they vary in objective and scope. ASPICE provides a structure for overall software development best practices, while ISO 26262 specifically deals with the functional safety of electrical and electronic systems within a vehicle.

2. Benefits of ASPICE Compliance

Despite being focused only on automotive software, ASPICE compliance has several positive downstream effects that affect the project quality, customer experience, and ultimately business profitability and stability.

- Enhancing software quality and reliability: By giving you a framework for evaluating software development processes, ASPICE helps you eliminate inefficiencies and errors. As a result, it helps to reduce the likelihood of serious downstream consequences.

If errors still slip through, you can always use impact assessment tools.

- Ensuring compliance and safety: ASPICE compliance gives your company a solid foundation for safety engineering. Aside from staying in-line with regulatory authorities, compliance also opens business opportunities as car makers look to ASPICE compliance as a sign of quality software.

For instance, Daimler-Benz says a partner “must verify a continuous ASPICE Level 3 to ensure the supply from the Start of Production (SOP).” - Improving project management: ASPICE gives you control and visibility into the development progress and helps you manage increasingly complex projects.

- Risk mitigation: ASPICE requires organizations to establish risk management processes. Steps include identifying risks, analyzing their impact, risk mitigation, and continuous monitoring. For instance, the 13 Project Requirements guideline requires firms to “Identify risks associated with project life cycle and with suppliers” and “Assure that all identified risks are communicated to the relevant parties.”

Within the requirements management tools built into Modern Requirement4DevOps, you can use features like traceability and version control to improve your ASPICE risk management compliance.

- Satisfying changing market demands: According to the World Economic Forum, “90% of future differentiating car features are software-based.” To keep up with these developments, ASPICE compliant automotive software related suppliers will play an increasingly large role in satisfying customer demands.

For example, South Korean chip semiconductor manufacturer SY Kynix announced in June 2023 that it was ASPICE Level 2 compliant. Their reasoning was that with “systems for Advanced Driver Assistance System and Infotainment getting more sophisticated, the importance of software quality management as well as compatibility and stability is growing, requiring auto part suppliers to obtain the ASPICE Level 2 or the equivalent.”

- Other benefits of ASPICE compliance include reducing downstream costs, increasing team productivity, and increasing customer satisfaction.

3. Implementing ASPICE in Automotive Software Development

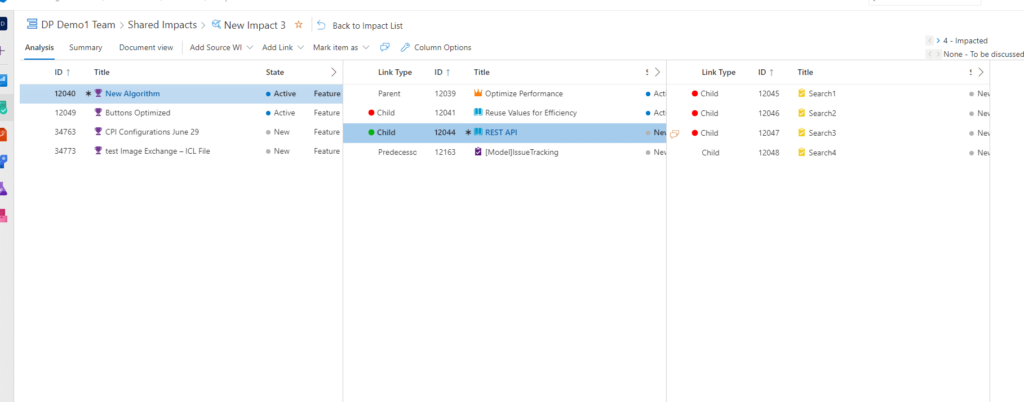

Implementing ASPICE in a company requires several steps. The steps below are not exhaustive, but they give a general overview of the high-level flow of ASPICE implementation in software. The specific activities your company carries out depend on your company’s type and circumstances.

- Understand ASPICE: Thoroughly understand the ASPICE framework, its principles, and requirements, PRM, and PAM.

- Gap Analysis and Process Definition: Assess your current processes against ASPICE requirements. Define the processes and procedures you need to have in place to be compliant.

- Process Implementation and Training: Implement the processes and procedures defined above. Train employees to ensure compliance with ASPICE.

- Process Monitoring, Measurement, and Improvement: Continuously monitor, measure, and iterate the ASPICE-compliant processes.

- Internal and External Assessments: Conduct internal assessments and seek external assessments through lead assessors.

- Supplier Collaboration: Collaborate with downstream and upstream suppliers to ensure their compliance with ASPICE.

- Documentation and Reporting: Maintain comprehensive documentation and reporting of ASPICE-related activities.

Several large car companies and suppliers have implemented ASPICE into their processes. For example, a car infotainment system developer called Acsia Technologies has recently received approval to develop ASPICE-compliant systems for BMW.

4. Automotive SPICE Certification and Assessment

An ASPICE assessment is done by a certified lead assessor, called a Competent or Principal Assessor, and their team of assessors. They evaluate the development capabilities of an automotive supplier using interviews and document reviews.

The assessment team then documents the results and compares them to the expectations of the ASPICE model to assign a process maturity score.

Your processes may undergo an ASPICE compliance assessment for several reasons:

- As prerequisite for the supply contract

- Process improvement

- Standardization and comparability of the assessment

5. ASPICE Compliance – The Future

Mobility without software is increasingly impossible – especially in the developed world. We are in the thick of a revolution in the automotive industry, driven by electrification, digitization, and changing customer expectations. Companies that don’t keep up will fall by the wayside.

A single car project can take anywhere between two to five years from concept to production. In the middle of this, there are plenty of gaps your project can fall through. But with the right set of tools (increasingly powered by AI), you can manage requirements, teams, and tests while staying compliant, profitable, and favored by customers.

With software comes complexity and abstraction. You can only manage the automotive industry’s unique combination of software and hardware through sound processes. Automotive SPICE is only a small part of a much larger puzzle, but organizations that embrace a philosophy of continuous growth, innovation, and success will surely flourish.